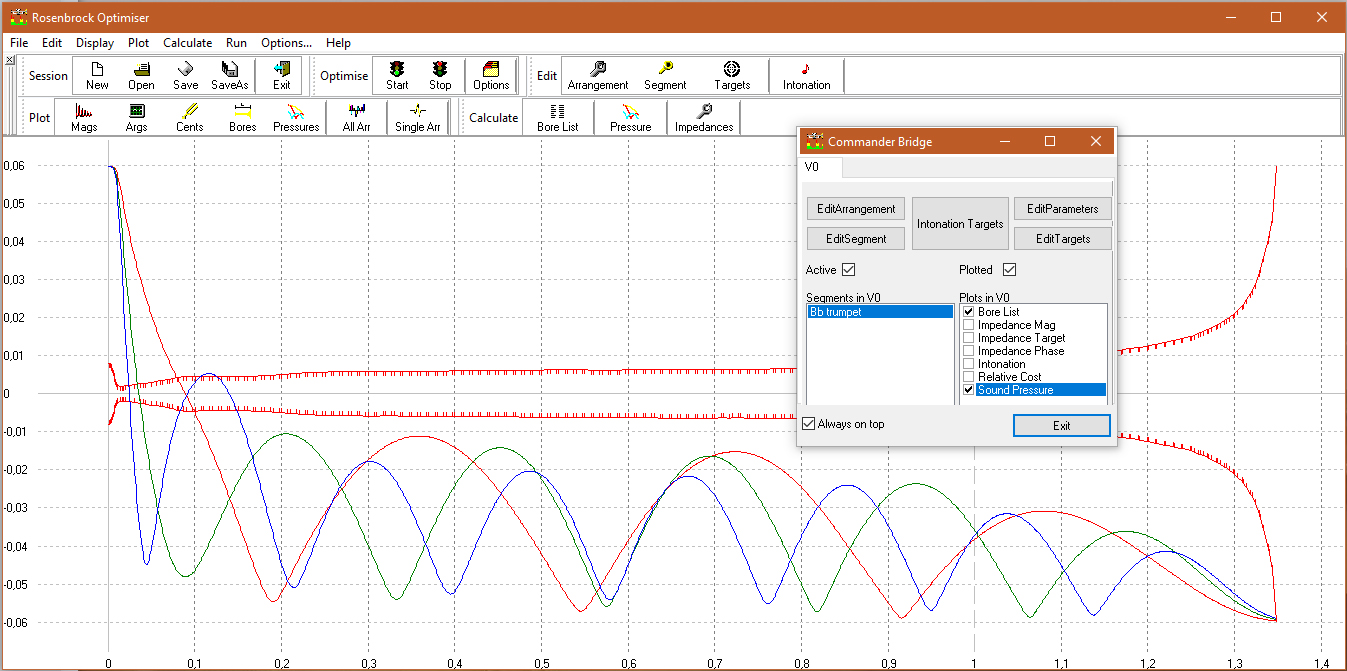

For example, select 3 tones from these naturals possible with this valve combination (in the illustration these are the 4th, 6th and 8th naturals) by simply deleting the rest from the list. Click on “Calculate Pressure Curves” in the menu in the main screen and then on “View Pressure Curves” Done! As seen in the Commander Bridge, the impedance, intonation and other parameters could also be displayed.

You can stop a running optimization at any time, save the intermediate status and then continue optimizing.

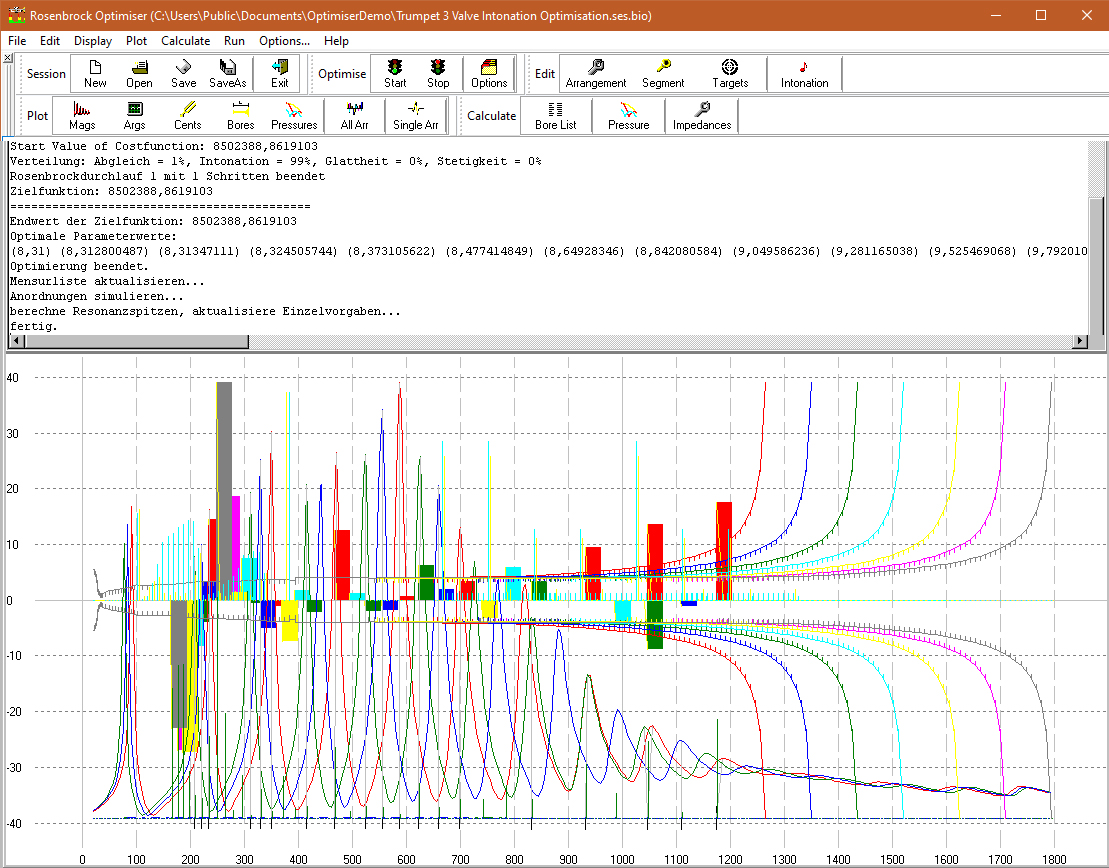

During an optimization you can see in real time at which points of the instrument the optimizer changes something and at the same time how these changes affect e.g. the intonation and response.

You can intervene at any time during the optimization and change the focus or set new priorities. If, for example, the correction of certain notes is more important to you than that of the other notes, or the envelope, i.e. the response is more important, then simply increase the “weighting” (this is a number) for the corresponding property – without interrupting the optimization.

MATCHING AND CLONING

When the optimization process is started, the optimizer calculates the impedance curve of the bore list given to it and tries to change the impedance curve belonging to this bore list so that it corresponds exactly to the curve loaded as the “Matching target”. To do this, it must modify its original bore list so that its impedance curve precisely matches the curve specified as the target. After completion of a successful optimization process, you will receive the bore list of the measured instrument and thus the exact construction instructions for a “clone” of this instrument.

However, this is a task for advanced users, since it is often necessary to modify various individual attributes and weightings during the optimization process.

Furthermore, for mathematical reasons, the complicated geometry of the mouthpiece at the very beginning of the instrument makes it difficult to match the two curves exactly. It is more convenient to perform a measurement of the instrument to be cloned without the mouthpiece and to omit the mouthpiece from the bore list as well.

However, the matching function is very suitable and is therefore recommended if you want to optimize an instrument, but your bore list is only inaccurate. In this case, the “Matchíng” of your bore list with the measured impedance curve is useful to get better results when optimizing.