The optimizer is already included in the BIAS PROFESSIONAL and BIAS ENTERPRISE edition.

HOW DOES THE OPTIMISER WORK?

The changes you wish to make to poorly tuned notes can be entered in this list as a percentage (musically: cent) or in absolute values (Hz).

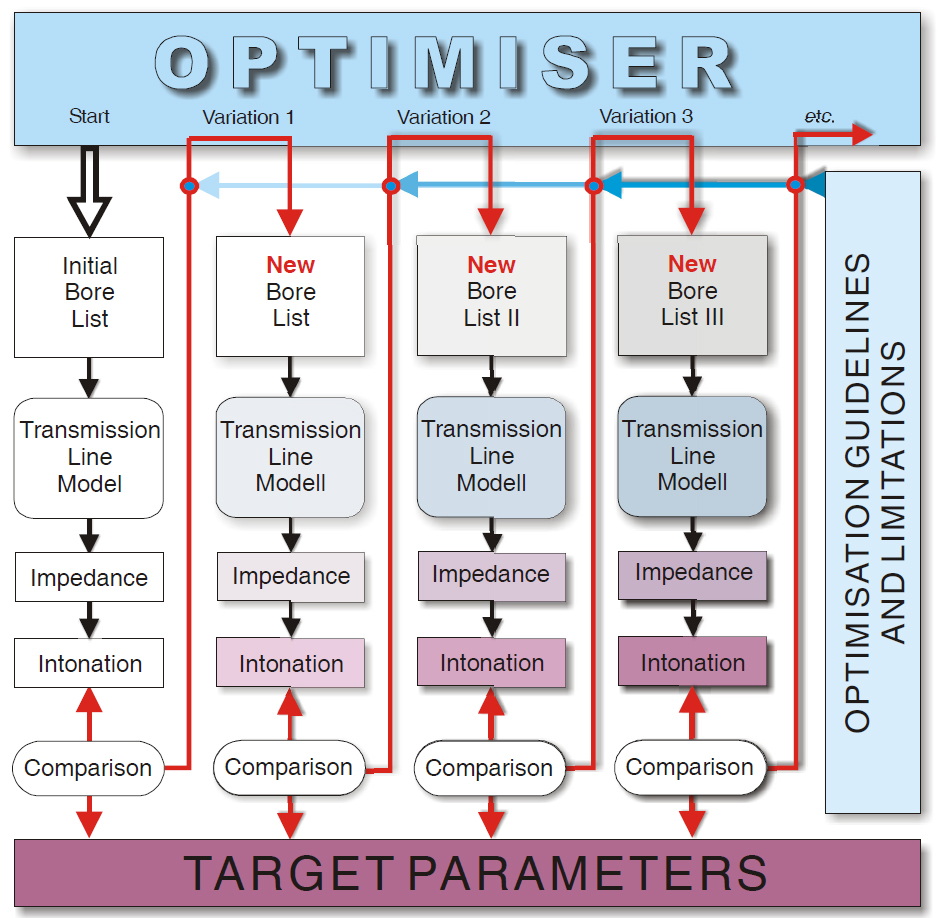

The optimizer now compares the existing intonation with your specifications and starts to change the bore (widening or narrowing at certain points). It then calculates the impedance and intonation and compares the new intonation with the old one. If it is better, he makes further steps in this direction, if not, he tries changes in other directions. This happens relatively fast and in one hour he has made several thousands of such calculations. The following figure shows the procedure.

For example, where the software may change the bore and where not (in the valve section or in the mouthpiece, for example), or whether it may also change the length of a component and by how much. How much a local widening or narrowing may be maximum (in % or mm), how big the allowed step size may be and whether the cone of conical components may be changed or not, and so on. These settings are made in the X/Y list of the respective component.

At the beginning, this requires a certain amount of thinking, but after a while this is greatly reduced by experience in dealing with optimizations.